Wayne Edney is no stranger to hard work, patience and the spirit of self-reliance that defines every DIYer. In 1994, he completed the build of a Bristol Channel Cutter 28 from a bare hull. He spent eight years building the boat on a teacher’s salary, devoting his weekends and summers to the project.

“This was the culmination of a dream that had first come to light 20 years earlier after reading a cruising book by Erik Hiscock,” Wayne shared with us. “It had been a 20-year odyssey to finally launch my own cruising boat, so the boat was christened ‘Odyssey’ by my wife, Karen, and our two children, Annalise (11 years) and Erik (7 years).”

The yearslong build marked the start of an incredible adventure for the teacher and his family. Keep reading to find out how Sailrite could help this intrepid DIYer fulfill his lifelong dream of building and launching a sailboat.

The Hull Truth

The Bristol Channel Cutter Wayne ordered from the Sam L. Morse Company in 1986 was delivered to his house as a bare hull. Wayne eagerly got to work. “They say that you can learn a lot by reading and I read every boatbuilding book I could find. However, there is no substitute for experience. In 1981, I took a one year leave of absence from teaching to attend a yearlong apprentice program at the Landing Boat Shop in Kennebunkport, Maine. I helped build a Swampscott dory and a Buzzards Bay daysailor. The woodworking skills I learned there were invaluable for completing my boat.”

Throughout the eight-year build of “Odyssey,” Wayne learned many valuable lessons about patience and resourcefulness. “Obstacles can sometimes be blessings in disguise,” he told us. “Building a cruising boat on a teacher’s salary meant limited cash flow, so patience and making the most out of each piece of wood were valuable lessons learned. Looking at the interior of my finished boat, a friend once said, ‘I can’t believe that you built all of this!’ I can’t either, but as I look at each individual piece of wood, I can remember the care that went into forming it.”

Overcoming money challenges, every piece of wood became a part of the boat’s story — a story crafted with care and dedication.

Setting Sail

Once Wayne put the finishing touches on the “Odyssey,” he was more than eager to enjoy the fruits of his labor. In 2002, he took another leave of absence from teaching. The family set sail on a six-month cruise to Mexico. “We traveled from San Francisco to Cabo San Lucas to the mainland of Mexico and up into the Sea of Cortez.” Today, San Francisco Bay is their sailing playground, with week-long trips to the delta regions of Stockton and Sacramento.

Wayne learned to sail at the University of California, Davis. He enrolled in a sailing course for his physical education credit. “The course was taught on Sunfish boats. They were really small. When you made a mistake, you ended up in the cold water and were not likely to repeat that mistake.”

What began as a college course evolved into a lifelong love of sailing and the open sea. “Being close to nature and self-sufficiency are two of the greatest things about sailing and being on the water. Most people can remember the first time they came close to the sea and smelled the ocean even before they saw it. Sailing along beautiful shorelines, you are at home with the birds and animals living there.

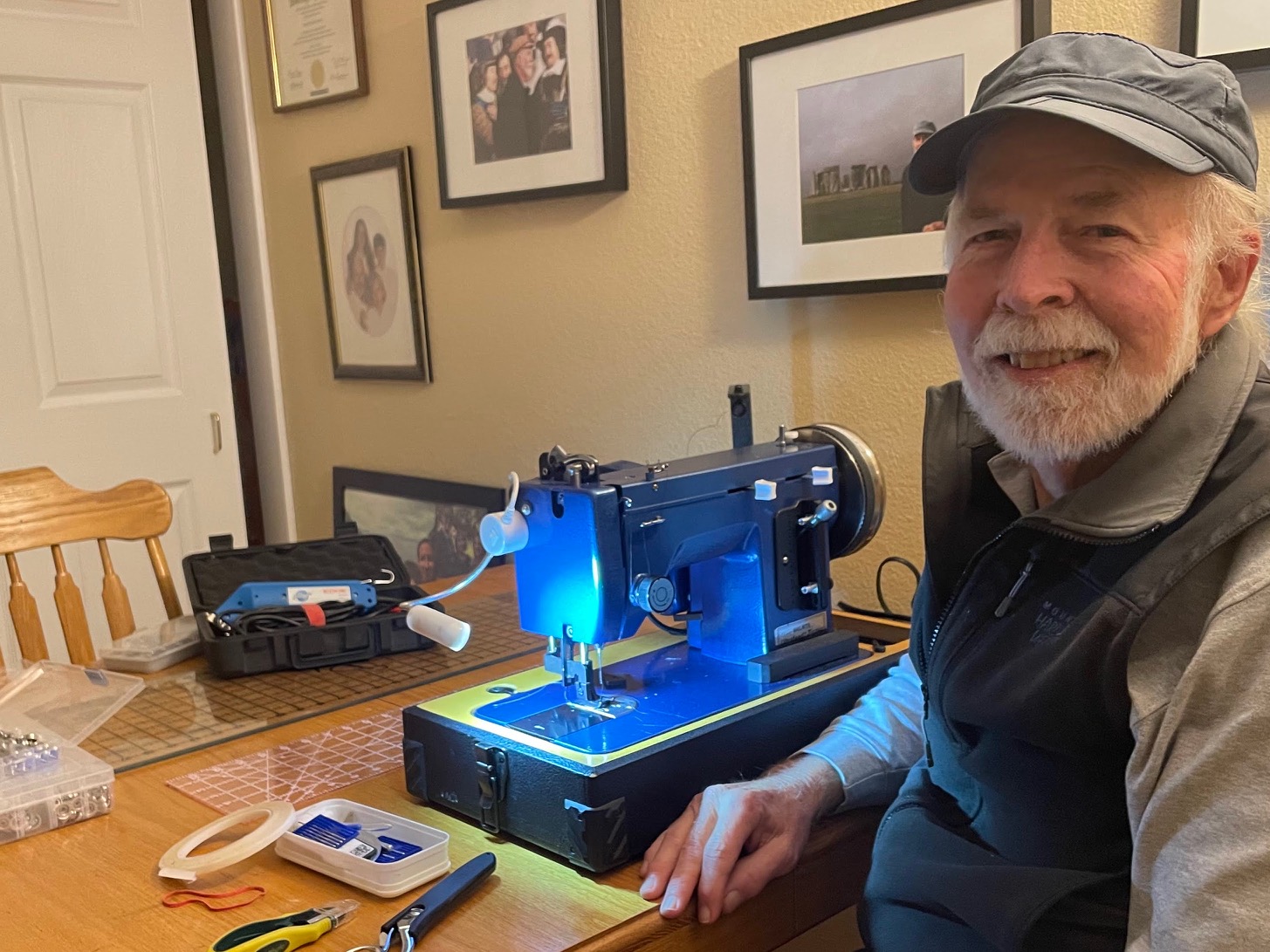

“Being on a cruising boat in this environment requires a certain level of self-sufficiency. I know how our boat was built. In addition, I know how to maintain it. Our Bristol Channel Cutter has beautiful bulwarks and I am often asked what I use to keep them looking so good. The secret is the Sunbrella® that covers them when the boat is not in use. My Sailrite® Ultrafeed® LSZ has been and continues to be an important tool for maintenance and self-sufficiency.”

The DIY of It All

Before the Mexico trip, Wayne had a dodger professionally installed on the boat. But after years in the sun and elements, the canvaswork and window vinyl were showing wear. Luckily, Wayne got a tip about a great DIY resource. “I first heard of Sailrite from other cruising sailors on our trip to Mexico. As the years went by, the dodger we had professionally made began to show signs of wear. With encouragement from Sailrite videos, I decided that I could remake the worn dodger panels. That was the beginning of lots of sewing projects.”

Wayne didn’t let his sewing inexperience stop him from tackling his own canvaswork projects. His desire to do things himself extends beyond boatbuilding. “I have learned to sew by trial and error. Most of my projects are on our boat. However, I find myself watching all kinds of Sailrite do-it-yourself videos that have nothing to do with my projects, but contain techniques that I can use.”

As a skilled builder, he knew he’d need the right tools to successfully sew the planned enclosure and other projects for his boat. That’s when Wayne knew the right tool for the job was the Ultrafeed LSZ. “When I married my wife, an old Kenmore sewing machine came with her. It did okay on simple projects but was not up to the challenge of sewing multiple layers of canvas or leather reinforcements. My Ultrafeed LSZ has been a game changer, allowing me to build my sewing skills with each project. I have made mistakes along the way, but each mistake has been a chance to learn techniques and more about the machine.”

Referencing Sailrite how-to videos, especially on dinghy chaps and dodger builds, expanded the teacher’s knowledge. Valuable skills like using basting tape, different seams, and Sailrite tools became crucial for successful projects.

Over the years Wayne has made dodger panels, mosquito screens, sail covers, cushions, curtains, a deck awning and more. Referencing Sailrite’s “How to Make Dinghy Chaps” video was a great help when a friend asked him to make the protective covers for his inflatable dinghy. “Valuable skills like using basting tape, the most common seams for canvaswork, and the advantage of tools like the acrylic patterning ruler, Edge hotknife and patterning material, all were crucial to the successful construction of the dinghy chaps,” Wayne shared.

Advice for Others

To those considering sewing their own canvaswork, Wayne’s advice is simple: “Go for it and don’t be afraid to make mistakes. Follow the Sailrite videos for completing smaller projects. Make sure that your machine and thread are set up properly. Every project is a lesson and an opportunity to learn and build confidence.”

After all, learning new skills keeps you young — a sentiment echoed by a teacher whose journey brought a dream to life, one stitch at a time.

Watch the video below of Wayne’s build from hull to launch!

Who We Are

Sailrite is your one-stop DIY shop! We are a passionate crew of do-it-yourselfers who strive to equip you with the supplies and how-to knowledge you need to tackle your next project. Do you want to learn upholstery, leatherwork, canvaswork, hobby sewing, bag making or more? We have the fabric, tools, hardware, sewing machines and notions you need to master any DIY. And even if you’ve never sewn before, our tutorials and how-to videos are designed for beginners and experienced crafters alike.

Start your DIY journey today: www.sailrite.com