“Nothing is impossible.”

That’s the motto of Linda Butters-Freund, a dedicated sewer and co-owner of Florida-based small business Offshore & More Custom Canvas LLC. Given her impressive 63 years of sewing experience, it’s safe to say that there’s no project she can’t tackle.

“There has never been a project too big for me,” Linda said when we asked her about the largest project she’s ever done. That project? A huge shade panel for the U.S. Open Pickleball Stadium’s championship arena, completed in early 2021.

The shade panel covers the open front of the championship stadium, which is in Naples, Florida. During pickleball tournaments, it provides players and spectators alike with much-needed relief from high heat and constant sun exposure. It’s a new and improved version of the original shade panel, which was made in 2017.

As a longtime Sailrite fan, Linda knew just where to turn for her project materials. She purchased enough spur grommets and webbing from Sailrite to complete the hanging shade panel — with some to spare.

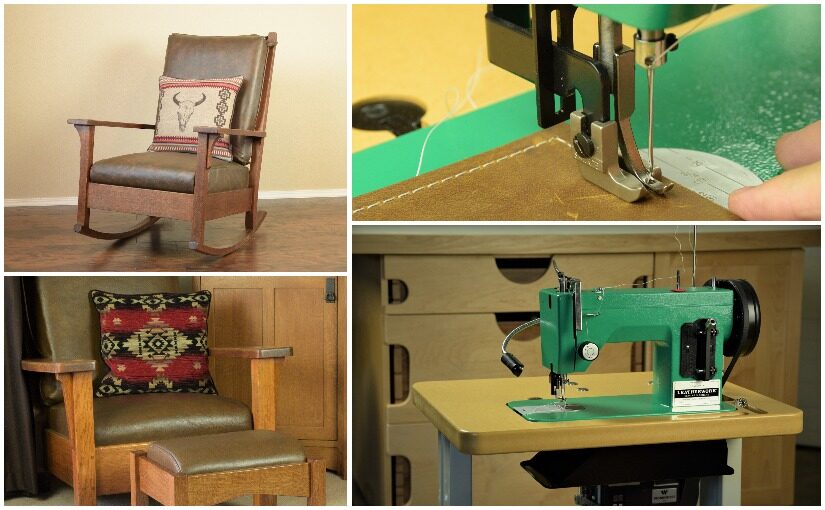

The panel’s massive scale made a large sewing machine a necessity. Luckily, Linda already owned a Sailrite® Professional Long Arm Sewing Machine when this project came around. With its extra-large throat, the Professional was the natural choice to sew the shade panel. “I honestly don’t think it would have been possible to use any other machine!” Linda said.

Introduction to Pickleball

Linda was already well acquainted with pickleball when she started working with the Naples stadium. She discovered the sport in 2012 while living on Florida’s Marco Island.

“I played tennis at the YMCA three times a week,” she explained. “I saw a flyer on the check-in counter announcing a clinic for pickleball. I signed up, started playing and realized that it was a much friendlier game … When I moved to Naples, I was fortunate to find a location nearby with lots of players.”

If you guessed that this “location nearby” was the U.S. Open Pickleball Stadium complex, you’re right on the money.

The stadium, which hosted the inaugural U.S. Open Pickleball Championships in 2016, consists of several open-air pickleball courts. Additionally, the championship court is covered by a large metal structure with fabric shade panels on the top and front. Linda started playing there before the original shade structure was built in 2017.

The Florida heat kept spectator numbers very low at the 2016 championships. Some shade, the stadium managers reasoned, would encourage more people to watch the tournament live in the future. They had the shade structure built soon after.

Although it greatly boosted attendance at the 2017 tournament, the structure had a major flaw. “[The] sunshades [were] made from a material that did not hold up to the elements,” Linda said. “[They] were fraying and the grommets were ripping out.”

The complex’s management needed someone to repair the shade panels — and they didn’t have far to look. Jim, the man in charge of the courts, soon learned about Linda’s sewing skills.

“[Jim] had seen some of my work from a player … I made personalized pickleball paddle covers. He asked [the player] for my name and contacted me,” Linda said. “I met with him, looked at the panels and said I would figure out a way to make repairs.”

Linda had never worked on such a large project before. But it’s never been in her nature to back down from a challenge. This tenacity and resourcefulness have served her well — starting when she learned to sew at 8 years old.

A Lifetime of Sewing Success

“I always watched my mother sewing clothes for my siblings and myself,” Linda said of her childhood. “I decided I would like to try my hand at it … I had some dolls that needed clothes! At that point everything I made was stitched by hand.”

It wasn’t long before Linda graduated from hand sewing to using a machine — after her search for just the right fabric for a project got a little out of hand.

“I decided to make a wedding dress for my Barbie® doll … I used my Easter dress slip/petticoat for the fabric. The ‘gown’ was beautiful! My mother was really impressed with my creativity until she realized what I had used to make it with!” Linda laughed.

Although upset that the dress slip was ruined, Linda’s mother saw that her daughter was serious about sewing. “[My mother] showed me the basics for using a sewing machine, gave me a box with extra fabrics and thread, and told me to have fun,” Linda remembered. “My world opened up and I knew sewing would always be a part of my life.”

In fact, sewing was Linda’s job long before she co-founded Offshore & More, and before she moved to Florida from the New England region.

In addition to teaching sewing classes, Linda has owned a dressmaking business (and in a humorous callback to her introduction to sewing, she made numerous wedding gowns). She also designed and sold canvas handbags at home showings similar to Tupperware® parties. The Massachusetts native had such success with her handbags that Yankee Magazine featured her in its small business section!

Later, Linda started her own marine canvas business after overhauling her family’s 40-foot yawl (a two-masted sailboat) with new upholstery and custom covers. Other than a short stint sewing for interior designers, she’s been entrenched in the marine sewing world ever since.

As an unstoppable entrepreneur, Linda has learned a lot about running a small business. When we asked what she would tell other aspiring business owners, she said this: “The most important advice I would give to someone who wants to start their own sewing business: LOVE what you’re doing! Every time I open the door from the house to my workshop, I look forward to working on projects.”

Sunshine, Shade Panels & Sailrite

Linda spent most of her life in the northern part of the East Coast — but by 2010, she was ready for a change of scenery. She decided to trade in bitter New England winters for the sandy beaches and ample boating opportunities of South Florida.

Around that time, she turned to Sailrite to bolster her marine sewing career. “I needed a company that would be able to supply all the tools and products required for my numerous projects. After hours of research, I came to the conclusion that Sailrite was my No. 1 choice!”

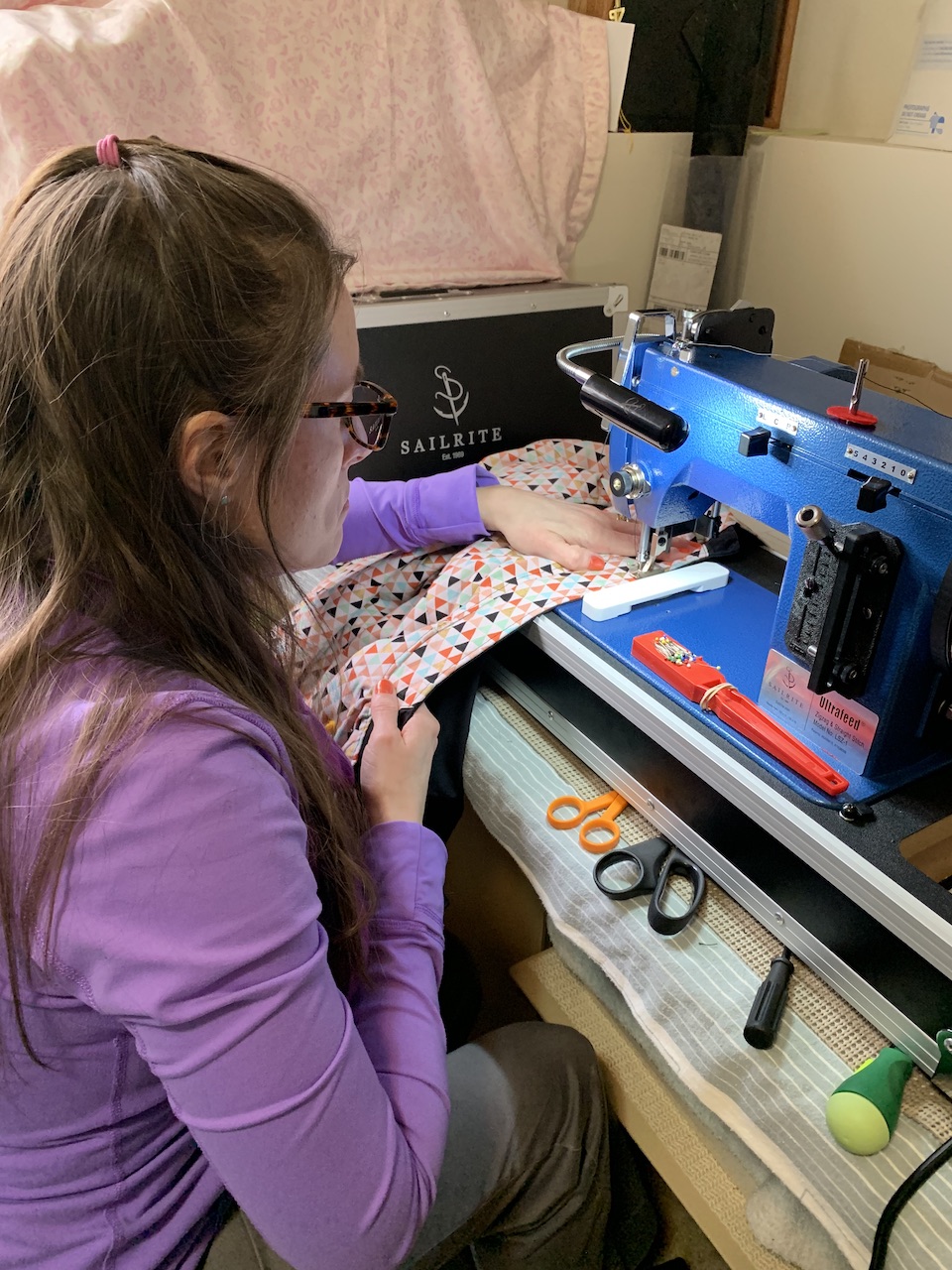

Linda’s familiarity with Sailrite was a big help when it came time to repair the pickleball stadium shade panels in Naples. She already owned an Ultrafeed® LS, but the large panels were often too bulky to fit through the compact machine’s throat. “I decided I needed a machine with a longer arm when I did repairs on the old shade panels,” she told us.

For this dedicated Sailrite fan, the perfect machine wasn’t hard to find. “Whenever a new project comes my way, I always do my research for supplies on the Sailrite website,” she said. “[It] is my go-to place to shop!”

That’s how Linda discovered the Professional Long Arm (now discontinued) and decided it was the upgrade she needed to repair the shade panel. “The added room under the arm made the ease of pushing 110-inch-wide material a breeze,” she said. “And being able to zigzag the rips really made the job easy!”

Thanks to this upgrade, Linda became the pickleball stadium’s go-to project person. She kept up with repairs on the original shade structure until 2020, when something happened that was too big to fix.

“A windstorm came through Naples and shredded the original stadium,” Linda said. “[It] had to be replaced due to hurricane-force winds.” There was no denying it — the shade panels on top of the original stadium were done for.

Somehow, the branded shade panel on the front of the stadium survived the storm. But its reign didn’t last much longer.

A new metal structure and shade panels were in place by the end of 2020. That’s when “[the stadium’s management] decided that the old shade panels [for the front] … needed to be replaced. They contacted the stadium company to inquire about purchasing material to match the [new] structure.”

Jim, the stadium’s manager, turned to Linda for help making the raw fabric into a single shade panel to cover the stadium’s front. It would be Linda’s largest project ever, but she was determined to face the challenge head-on.

The Making of a Shade Panel

Armed with the new shade fabric, her Professional Long Arm and the materials she purchased from Sailrite, Linda got to work on the front panel in January 2021. She didn’t have much time — that year’s Pickleball Championship tournament was scheduled for April. Fortunately, she also wasn’t alone.

You see, Linda’s son Michael and his family also live in Florida. Linda had taught him how to sew when he was growing up in Massachusetts, and he’d helped with some of her previous projects. Just like his mom, he’d caught the sewing fever.

“[Michael] wanted to get back into the canvas business,” Linda told us. “He asked me if I would like to make my boat canvas official. He wanted to have something to do when he wasn’t working his ‘real’ job.” Linda liked the idea, and Offshore & More Custom Canvas was born.

When Michael isn’t at his full-time job, he pitches in on Offshore & More’s projects, including the shade panel. Good thing, too — the shade panel called for large-scale measurements that would be difficult for one person to manage. Linda gave us the details:

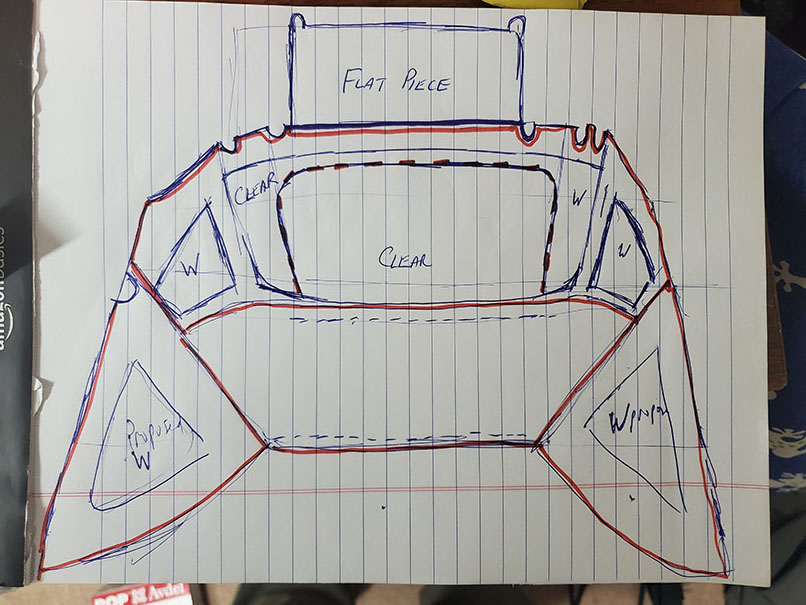

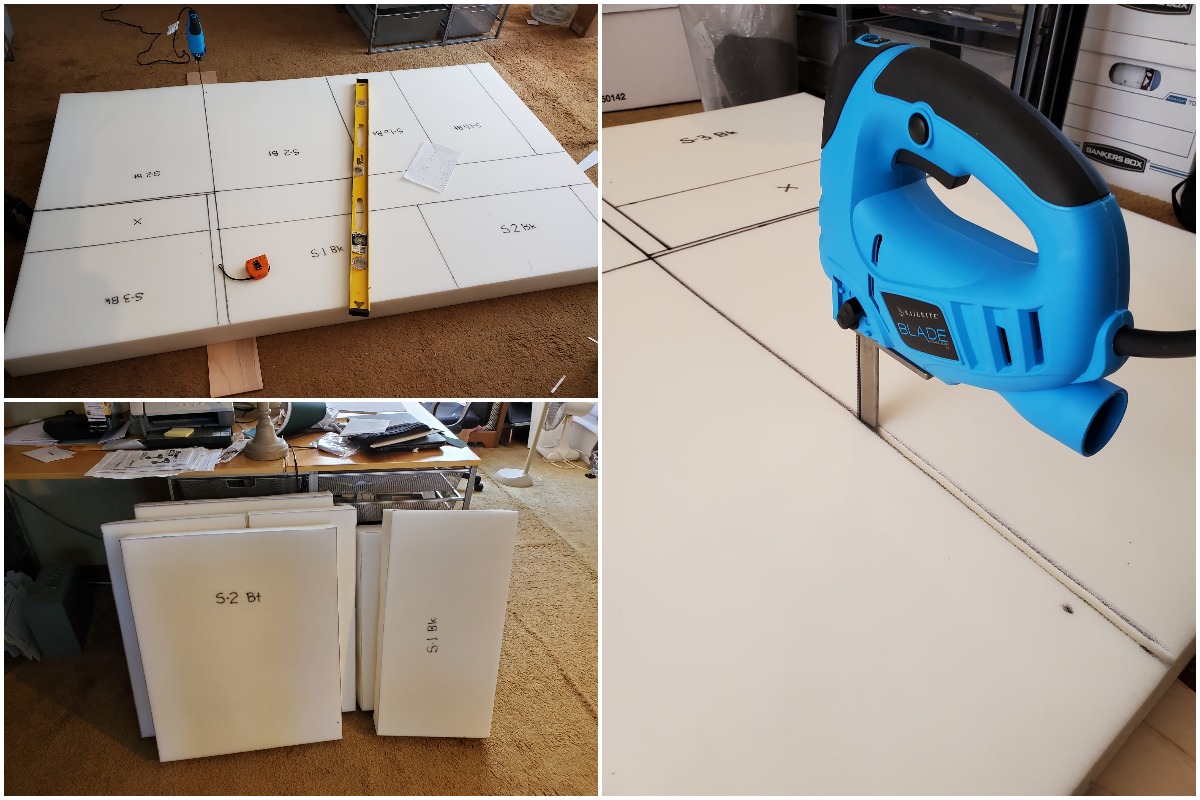

“The shade panel was made up of seven individual panels [and] measured 125 feet across the lower edge and 19 feet [tall] in the center.” The oversized panels required more space than Linda’s garage workshop could provide.

“Fortunately, we have a very large driveway,” she said. “I was able to place the three [center] panels on my driveway, line up the sides and mark for grommet placement. Since the top of the shade panel was arched, I had to roll part of the painted [center] panels to the side to mark and measure for the other four panels needed to complete the project.”

After measuring and cutting the panels, Linda turned to her trusty Professional Long Arm to sew them together. Then, it was time to install the grommets — which was when having a helper became indispensable.

Due to a hand injury, Linda couldn’t use a hammer to install the incredible 650 spur grommets that the project called for. Instead, “Michael was enlisted to mark and install the grommets,” she told us. “He saved the day.”

Besides the 650 grommets, the mother-son team went through 110 yards of shade cloth and nearly 800 feet of webbing. Including a three-week screen-printing process — which required Linda to ship the giant panels to a printer on a pallet — the whole project took two months of hard work. Linda and Michael finished the shade panel in March 2021, just in time for the U.S. Open tournament the following month.

The Creativity Continues

Although the shade panel has been done for over a year, Linda still checks in on it now and again — and she feels as proud of it today as she was the day it was completed. “I love opening up a pickleball magazine and seeing the finished project in full color,” she told us.

In fact, that sense of accomplishment is one of the things Linda loves most about her DIY lifestyle. “I can take a simple piece of material and create something unique,” she said. “Once the project is completed, I’m left with the feeling, ‘Yes, I made that!’”

Sewing is her first love, but it isn’t Linda’s only DIY hobby. She told us she also enjoys watercolor painting and gardening. “The weather in Florida has proven to be a challenge though,” she said of gardening. “If you forget to water one day, the plants are toast!”

But remember, Linda isn’t the type to give up when things get tough. Whether it’s gardening in the Florida weather, digging up repair manuals to fix an old lawnmower or using Sailrite’s free how-to videos to learn a new sewing project, Linda embodies the go-getter spirit of a true DIYer. “I’m happy as long as I’m doing something creative,” she said.

We certainly understand that, Linda! Thank you for sharing your story — we know that your creativity and tenacity will inspire your fellow DIYers to make great things. Best of luck on all your future projects!

Who We Are

Sailrite is your one-stop DIY shop! We are a passionate crew of do-it-yourselfers who strive to equip you with the supplies and how-to knowledge you need to tackle your next project. Do you want to learn upholstery, leatherwork, canvaswork, hobby sewing, bag making or more? We have the fabric, tools, hardware, sewing machines and notions you need to master any DIY. And even if you’ve never sewn before, our tutorials and how-to videos are designed for beginners and experienced crafters alike.

Start your DIY journey today: www.sailrite.com